For environmental air quality monitoring, Cubic has developed the light-scattering online particle counter based on core technology platform. The products use a high-power industrial-grade laser and photoelectric conversion technology to detect airborne particles in real time across six size ranges.

- HVAC Transmitter AM6108B

- IAQ Transmitter AM6108A

- Wall Mount Transmitter AM6208W

- Duct Mount Transmitter AM6208D

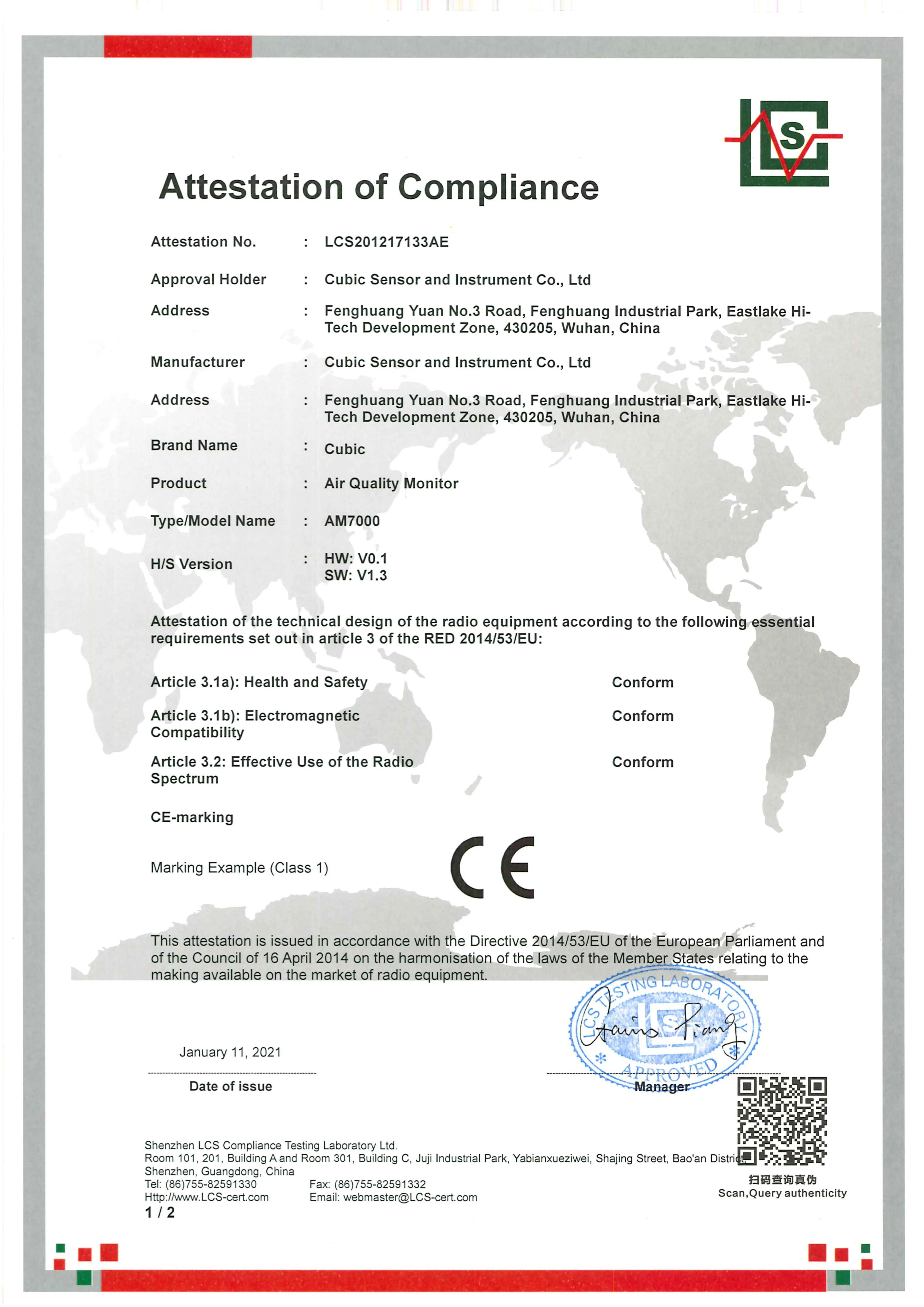

- Desktop Air Quality Monitor AM7000

- Mini CO2 Detector CM01

- 28.3LPM Portable Optical Particle Counter OPC-6511DS

- 28.3LPM Online Particle Counter with Display OPC-6510DS

- 28.3LPM Online Particle Counter without Display OPC-6510

- 2.83LPM Online Particle Counter with Display OPC-6303DS

- 2.83LPM Online Particle Counter without Display OPC-6303M

- Explosion-proof Particle Counter OPC-6303FB

- Optical Aerosol Spectrometer OPC-6510A

What are you looking for?