Manufacturing Process Monitoring Demands

Industrial manufacturing environments operate under continuous production conditions where environmental parameters and safety are critical. Across a wide range of manufacturing sectors, operations rely on facility-level monitoring to maintain stable environmental conditions. Sensing systems support manufacturing facilities by providing accurate, reliable measurement data over long operating cycles.

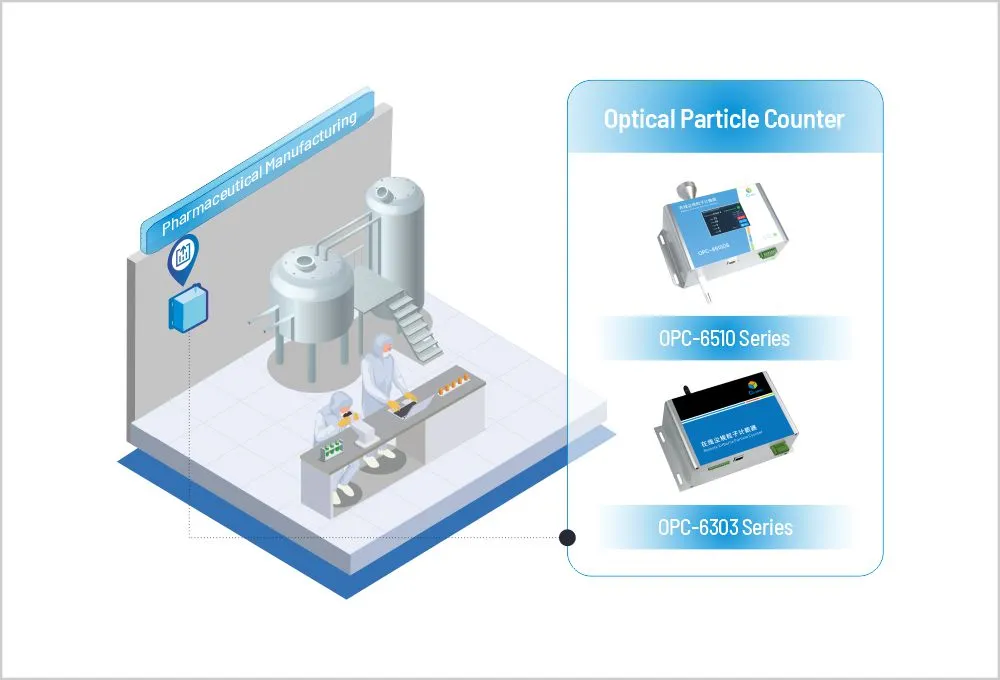

Environmental Air Quality Monitoring

Environmental air quality monitoring is a foundational dimension of facility-level inspection in industrial manufacturing environments. Stable environmental conditions including airborne particle concentration, temperature, humidity, and overall indoor air quality are essential for maintaining product quality and operating compliance across manufacturing processes.

The environmental air quality monitoring systems are commonly designed in alignment with international standards such as ISO, enabling consistent assessment of controlled environments across different manufacturing sites. For example, elevated airborne particle levels beyond certain environmental limits may increase the risk of contamination within production areas, potentially affecting product consistency and compliance with quality requirements. Environmental air quality monitoring enables early identification of such conditions, allowing corrective actions to be taken at the environmental management level before safety or quality risks escalate.

Production Safety Monitoring

Production safety monitoring is a critical aspect particularly in manufacturing processes where hazardous, toxic, or reactive gases are present. Continuous monitoring is required to detect abnormal conditions early and support timely response to potential safety risks.

At the facility level, safety monitoring focuses on gas presence, concentration thresholds, and changes in surrounding environmental conditions, thereby supporting personnel protection, equipment safety, and compliance with industrial safety regulations. Production safety monitoring solutions are typically designed in accordance with international standards such as ISO and IEC and are integrated into facility safety and alarm systems. Their purpose is to provide real-time visibility and early warning for safety management and emergency response.

Cubic Manufacturing Process Gas Sensing Solutions

With over 20 years of expertise in sensing technology R&D, Cubic—a leading manufacturer of gas sensors and analyzers—delivers advanced gas sensing solutions tailored to the above two key dimensions of manufacturing process: environmental air quality and safety production monitoring.

For environmental air quality monitoring, Cubic has developed the online optical particle counter based on light-scattering core technology platform. The device uses a high-power industrial-grade laser and photoelectric conversion technology to detect airborne particles in real time across wide measurement range. The level of precision is essential for evaluating cleanroom performance in accordance with ISO 14644 standards and supports continuous monitoring in critical production areas. The online optical particle counter features a 3.5-inch multilingual touch screen and supports both RS485 and MQTT protocols for flexible integration. In addition, Cubic offers IAQ transmitters based on NDIR and MEMS MOX technology for real-time monitoring of temperature and humidity. The IAQ transmitters support wireless monitoring, making installation flexible and reducing the need for wiring. With a built-in touch screen, users can easily view data, adjust settings, and perform on-site calibration.

Cubic also delivers robust solutions for production safety monitoring in manufacturing process, where toxic and reactive gases are widely used. Leaks of the gases pose serious risks to personnel and equipment, making early detection critical. Based on dual-beam NDIR technology, Cubic develops gas sensors specifically designed for monitoring tungsten hexafluoride (WF₆) and silicon tetrafluoride (SiF₄), which are widely used in manufacturing process. The solution provides high accuracy, long-term stability, and reliable performance in continuous monitoring applications.

Applications

Cubic gas sensing solutions are designed for use across a wide range of manufacturing applications where accurate monitoring of environmental conditions is required. The solutions support monitoring of environmental air quality and production safety. Typical application areas include electronics manufacturing, chemical processing environments, industrial laboratories, and other manufacturing sites that operate under controlled environmental and safety requirements. Across the applications, Cubic provides reliable measurement performance, long-term stability, and alignment with international standards to support consistent monitoring demands in diverse industrial settings.

As manufacturing environments across different industry sectors continue to evolve, the demand for precise and comprehensive monitoring solutions remains essential. With a strong foundation in core sensor development and customer-driven innovation, Cubic delivers industrial sensing solutions that emphasize measurement accuracy, long-term stability, and alignment with international standards, supporting controlled facility environments across multiple manufacturing sectors.

For more details, please visit https://www.cubic-controls.com/cubic-gas-monitoring-solutions-for-manufacturing-process/ or contact us sales@gassensor.com.cn .