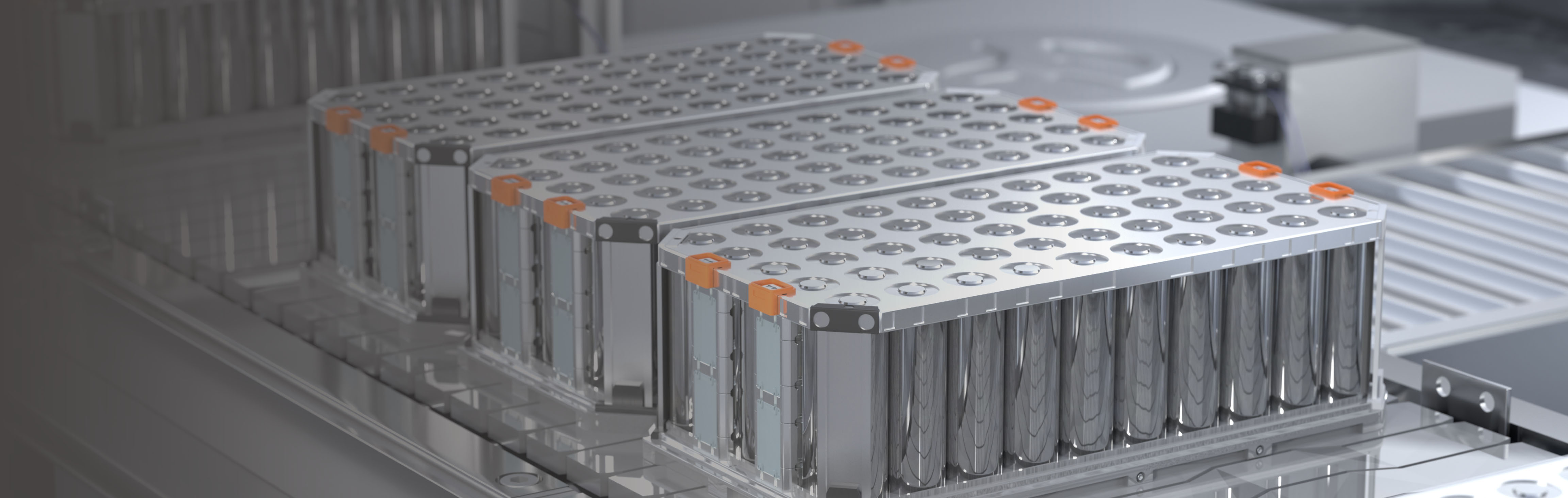

Particle counter is essential for contamination control in cleanrooms and dry rooms. Cubic has specially developed optical particle counters based on light scattering technology, which can detect airborne particles in real-time, ensuring compliance with ISO standards and minimizing the risk of defects. With high sensitivity and integration capabilities, Cubic optical particle counter could help protect sensitive materials and maintain ultra-clean manufacturing environments.

- HVAC Transmitter AM6108B

- IAQ Transmitter AM6108A

- Wall Mount Transmitter AM6208W

- Duct Mount Transmitter AM6208D

- Desktop Air Quality Monitor AM7000

- Mini CO2 Detector CM01

- 28.3LPM Portable Optical Particle Counter OPC-6511DS

- 28.3LPM Online Particle Counter with Display OPC-6510DS

- 28.3LPM Online Particle Counter without Display OPC-6510

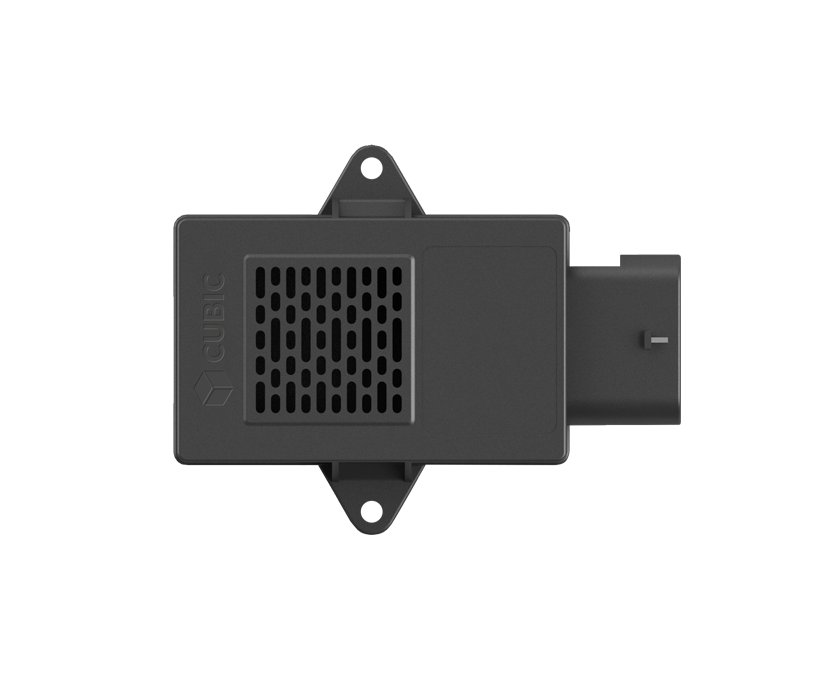

- 2.83LPM Online Particle Counter with Display OPC-6303DS

- 2.83LPM Online Particle Counter without Display OPC-6303M

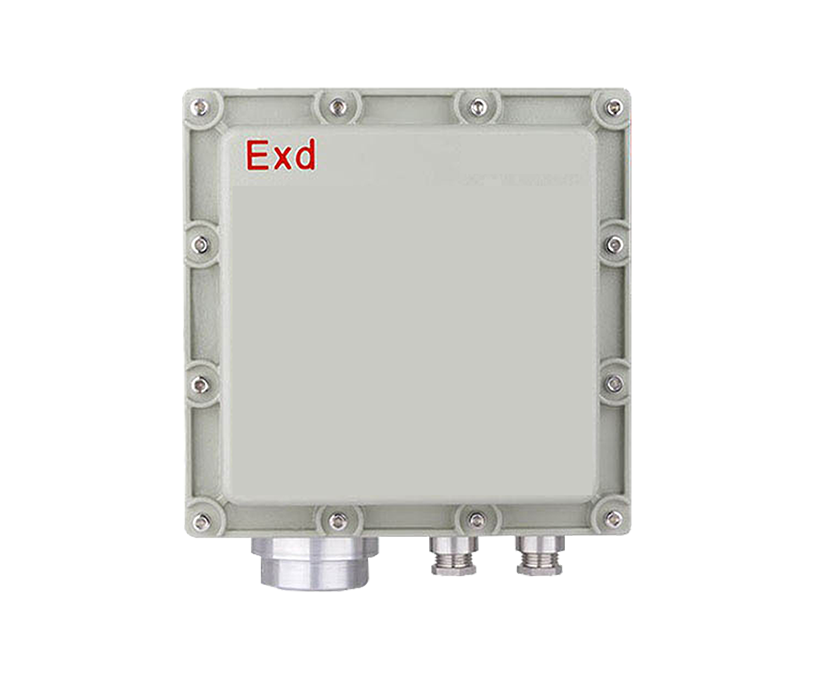

- Explosion-proof Particle Counter OPC-6303FB

- Optical Aerosol Spectrometer OPC-6510A

What are you looking for?

_20250731143159.webp)